China fiberglass curtain wall mesh 10x10mm factory

Fiberglass mesh for reinforcement, especially with a 10x10 mm mesh, is widely used in construction to strengthen plaster layers and building facades. Choosing a Reliablefiberglass mesh manufacturer– a key factor to ensure durability and quality of finishing work. In this article we will look at the main aspects of choosingChinese factories producing fiberglass mesh for curtain walls, as well as its areas of application and important characteristics.

What's happenedfiberglass mesh for curtain wallsand where is it used?

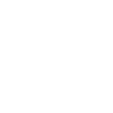

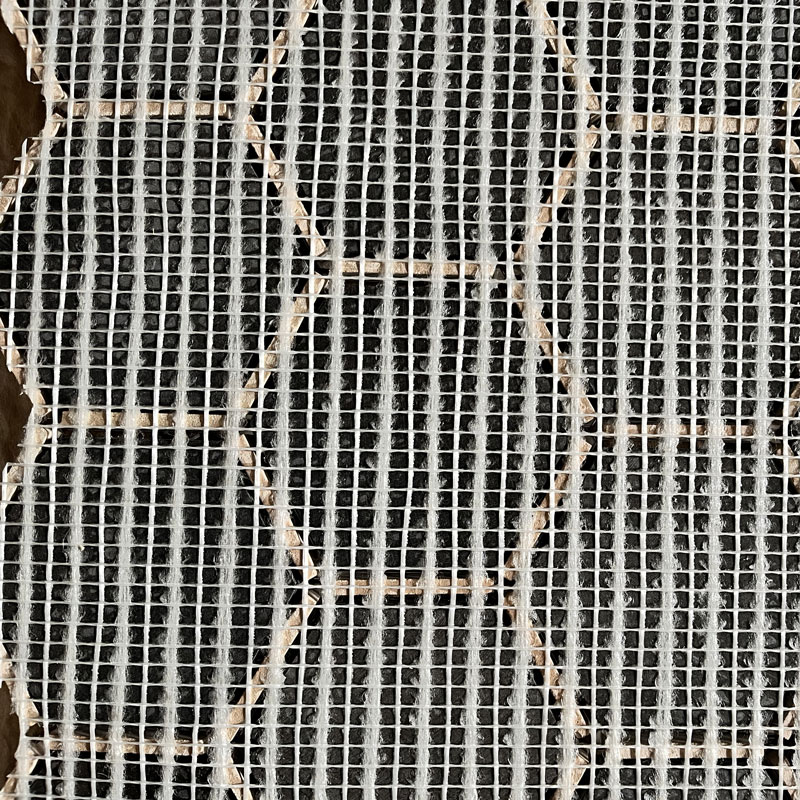

Fiberglass meshis a woven material made from glass fiber threads impregnated with special polymers to increase strength and resistance to environmental influences. The mesh cells are usually 10x10 mm in size, which provides an optimal combination of strength and flexibility.

Applicationsfiberglass mesh 10x10 mm:

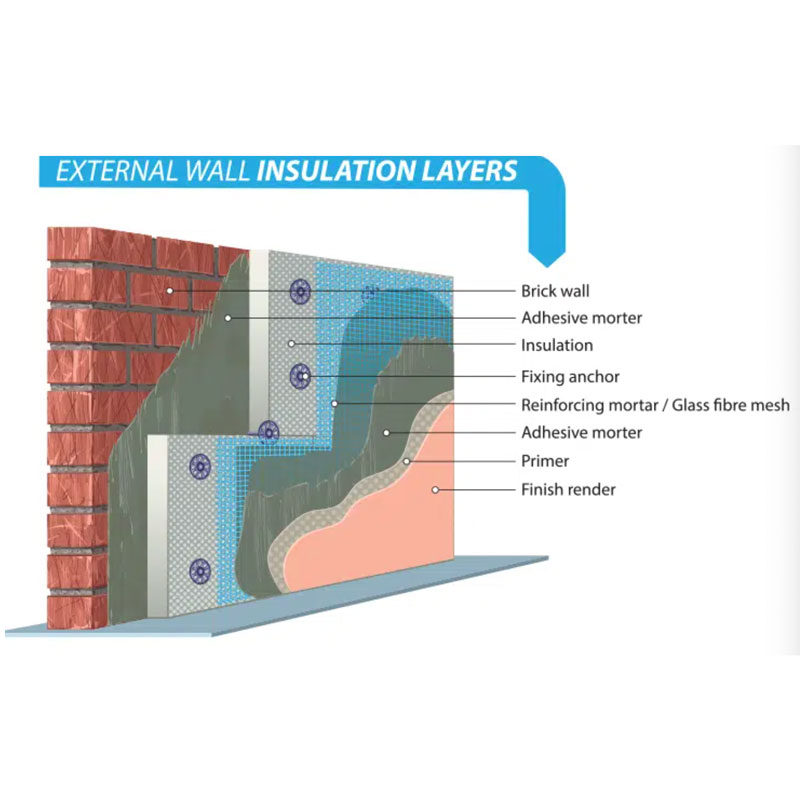

- Reinforcement of plaster and putty layers on building facades.

- Strengthening floor screeds.

- Protection against cracks and deformations in insulation systems.

- Изготовлениеcurtain walls(ventilated facades).

- Strengthening the junction of door and window openings.

How to choosefiberglass factory in China: key criteria

Choosing a reliable supplierfiberglass mesh- a responsible task. When choosingChinese factoryYou should pay attention to the following criteria:

Reputation and experience

First of all, study the history of the company, its experience in the market and customer reviews. The availability of certificates of compliance with international quality standards (ISO, CE) is an important indicator.

Production facilities and technologies

Make surefactoryhas modern equipment and uses advanced production technologies. This guarantees stable product quality and the ability to fulfill large orders.

Product range

Pay attention to the range of products offered. Availability of various typesfiberglass meshwith different densities and cell sizes will allow you to choose the best option for specific tasks.

Quality control

Find out what quality control methods are used in production. A reliable supplier should conduct regular testing of its products to ensure compliance with established requirements.

Pricing policy

Compare prices from differentфабрик, but don’t choose the cheapest option. A price that is too low may indicate low quality products.

Logistics and delivery conditions

Discuss delivery terms, delivery times and costs. Make sure that the supplier can ensure reliable and timely delivery of goods to your warehouse.

Our companyHebei Blue Diamond International Co.,Ltd, is a reliable supplierfiberglass meshот ведущихChinese factories. We offer a wide range of high quality products at competitive prices.

Characteristicsfiberglass mesh 10x10 mm

Key characteristics to look for when choosingfiberglass mesh:

Density

Densitymeshmeasured in grams per square meter (g/m2). The higher the density, the stronger and more durable the material. For facade work it is recommended to usemeshwith a density of at least 160 g/m2.

Cell size

The cell size determines the degree of reinforcement.Mesh with mesh 10x10 mmis the optimal choice for most construction tasks.

Tensile strength

Tensile strength characterizes the abilitymeshwithstand loads. For facade work, this figure must be at least 2000 N/5 cm.

Alkali resistance

Alkali resistance is an important parameter that determines stabilitymeshto the effects of alkaline media contained in cement mortars. Choosemeshwith high alkali resistance to ensure its durability.

Impregnation content

The content of polymer impregnation affects strength and stabilitymeshto atmospheric influences. The higher the impregnation content, the better the protectionnetfrom moisture and ultraviolet radiation.

The table below shows approximate characteristicsfiberglass mesh 10x10 mmvarious manufacturers:

| Characteristic | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Density (g/m2) | 160 | 145 | 180 |

| Tensile strength (N/5cm) | 2200 | 2000 | 2400 |

| Alkali resistance (%) | 95 | 90 | 98 |

Installationfiberglass mesh

Correct installationfiberglass mesh– the key to the durability and reliability of the reinforced layer. Follow the manufacturer's recommendations and use quality materials.

Main stages of installation:

- Surface preparation: cleaning from dust, dirt and other contaminants.

- Applying the first layer of plaster or putty.

- Layingfiberglass meshwith an overlap of at least 10 cm.

- Recessingmeshinto a layer of plaster or putty.

- Applying a second layer of plaster or putty.

- Leveling the surface.

Benefits of working withChinese fiberglass factories

Orderfiberglass meshdirectly fromChinese factorieshas a number of advantages:

- Lower prices compared to European or American manufacturers.

- Wide range of products.

- Possibility of ordering products according to individual requirements.

However, when working withChinese factoriesit is necessary to take into account possible risks associated with product quality and logistics. Therefore, it is important to choose reliable suppliers and carefully control the quality of the goods.

Choosingfiberglass mesh for curtain walls, pay attention to reputationfactories, product characteristics and delivery conditions. We hope this article helped you better understand this issue. If you have any questions, contact our specialistsHebei Blue Diamond International Co.,Ltdfor advice.

Correspondingproducts

Related Products

Best Sellingproducts

Best Selling Products-

Fiberglass Mesh Fabric for EPS Special Improvement Line

Fiberglass Mesh Fabric for EPS Special Improvement Line -

Fiberglass mesh for roof waterproofing

Fiberglass mesh for roof waterproofing -

Fiberglass mesh tape

Fiberglass mesh tape -

Fiberglass Window Screen

Fiberglass Window Screen -

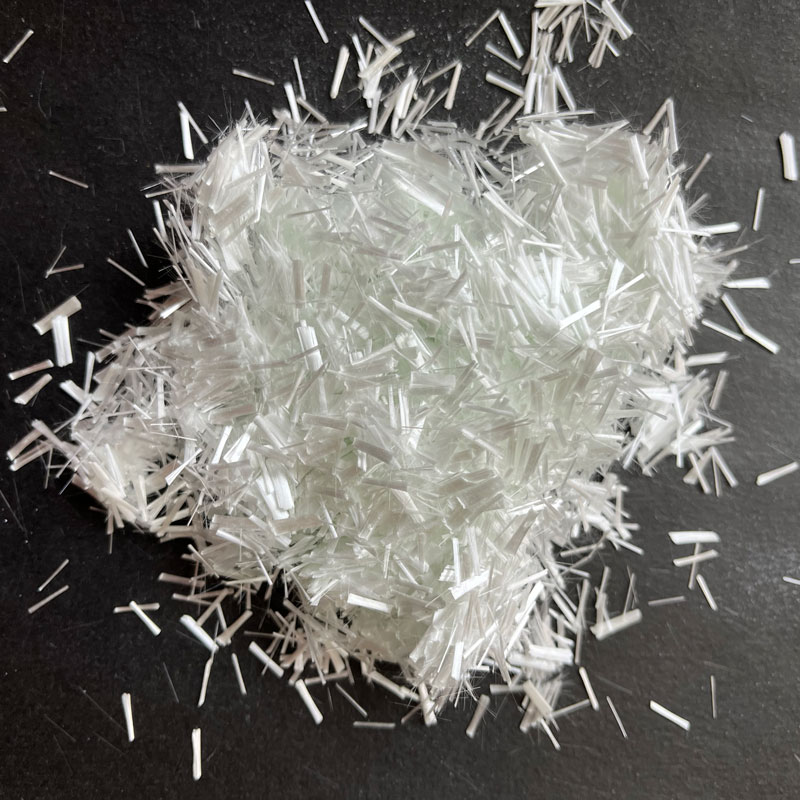

AR fiberglass cut thread

AR fiberglass cut thread -

Fiberglass Mesh Fabric for Reinforcement of Stone and Mosaic Substrate

Fiberglass Mesh Fabric for Reinforcement of Stone and Mosaic Substrate -

Fiberglass mesh fabric for wall insulation and reinforcement.

Fiberglass mesh fabric for wall insulation and reinforcement. -

Fiberglass reinforced plastic board

Fiberglass reinforced plastic board -

Metal Corner Tape

Metal Corner Tape -

PVC corner edge

PVC corner edge -

Spray masking protective film

Spray masking protective film -

Fiberglass woven roving

Fiberglass woven roving

Connectedsearch

Related Search- Cheap Suppliers Certified Fiberglass Plaster Mesh Fabric

- China manufacturer fiberglass curtain wall mesh certificate

- Cheap Manufacturers Fiberglass Mesh Painters Network

- China manufacturer fiberglass curtain wall mesh krepix

- Cheap fiberglass mesh fabric suppliers

- Manufacturers of cheap pvc fiberglass masonry mesh

- fiberglass mesh

- China Suppliers Fiberglass Mesh Fabric for Painting

- China suppliers plaster mesh fabric 2

- Chinese suppliers fiberglass exterior wall plaster mesh fabric price