China manufacturer plaster mesh rolls

Find a reliable Chinese manufacturerplaster mesh rollscan be a challenging task. In this article, we'll look at key selection considerations, from mesh types to important specifications, to help you make the right choice for your construction projects. Hebei Blue Diamond International Co., Ltd. offers a wide range of products to meet the requirements of various projects. Issues related to materials, application and benefits of using high-qualityplaster mesh rolls.

Types of plaster mesh in rolls: Overview

Plaster mesh rollsare presented in various types, each of which is designed for specific tasks. The choice of the appropriate type directly affects the quality and durability of the plaster layer. Let's look at the main types:

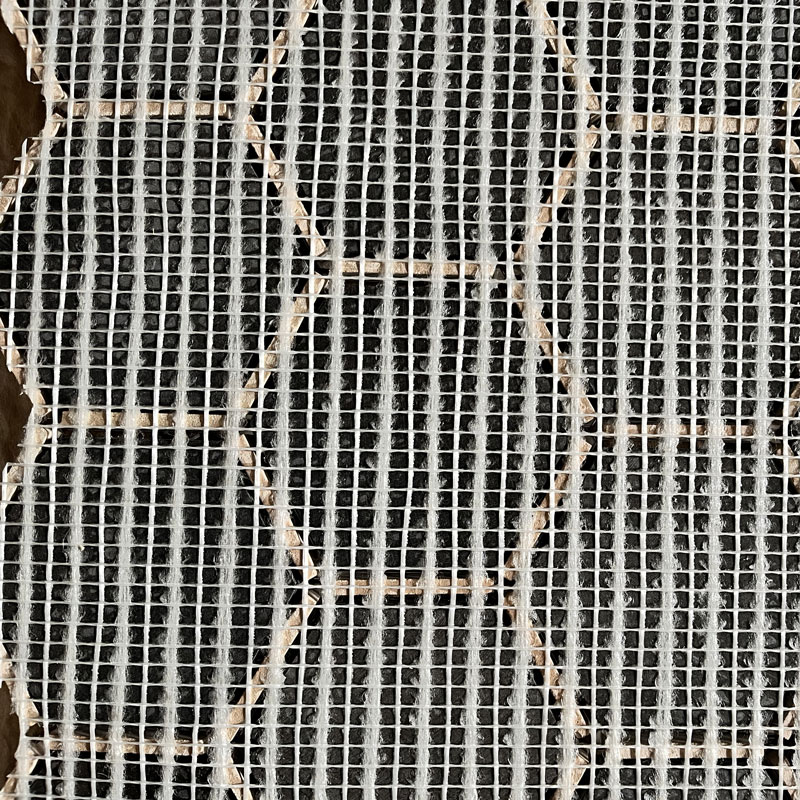

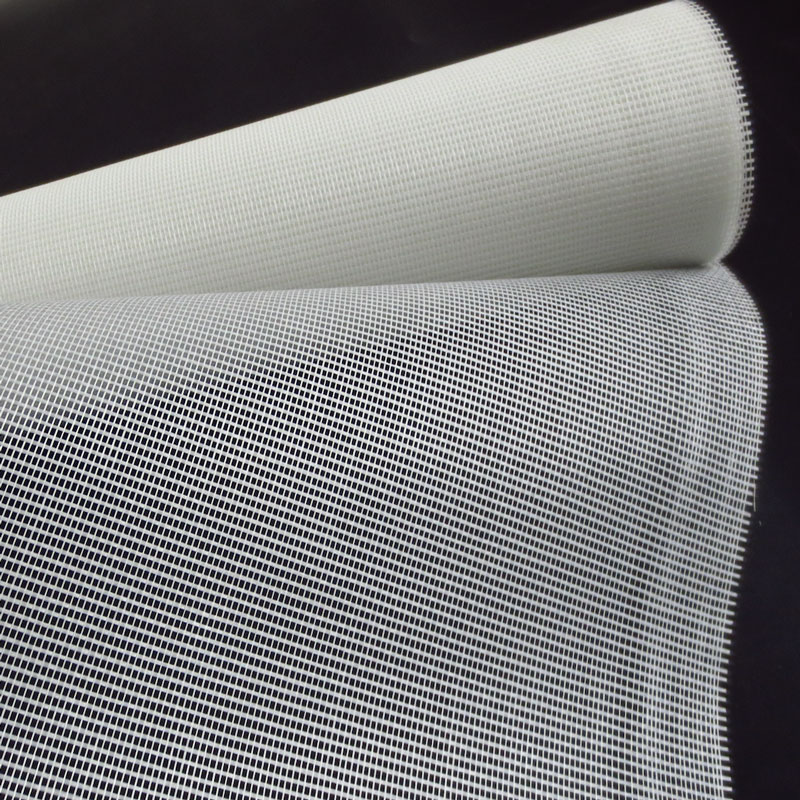

Fiberglass mesh

Fiberglass mesh is the most common type used to reinforce plaster layers both indoors and outdoors. It has high tensile strength and is resistant to alkalis contained in plaster solutions. Hebei Blue Diamond International Co., Ltd. offers a wide selection of fiberglass mesh of various densities and mesh sizes.

Metal mesh

Metal mesh is usually made of galvanized steel or stainless steel. It is used for reinforcing plaster layers under conditions of increased loads, for example, on building facades or in industrial premises. The metal mesh has high strength and resistance to mechanical damage.

Polymer mesh

The polymer mesh is made of polypropylene or polyethylene. It is lightweight, durable and resistant to moisture and chemicals. Polymer mesh is used to reinforce plaster layers on difficult surfaces or in conditions of high humidity.

Key characteristics of plaster mesh in rolls

When choosingplaster mesh rollsIt is important to consider the following characteristics:

- Density:It is measured in grams per square meter (g/m2). Higher density means greater mesh strength.

- Cell size:Affects the degree of reinforcement of the plaster layer. Small cells provide more even load distribution.

- Material:Determines the strength, environmental resistance and durability of the mesh.

- Roll width:Selected depending on the size of the surface being treated.

- Roll length:Affects ease of transportation and storage.

How to choose a Chinese manufacturer of plaster mesh in rolls

Search for a reliable Chinese manufacturerplaster mesh rollsrequires a careful approach. Please note the following factors:

- Manufacturer reputation:Study customer reviews, check for certificates of quality and compliance with standards.

- Product range:Make sure the manufacturer offers a wide selectionplaster mesh rollsvarious types and characteristics.

- Production capacity:Assess the scale of production and the availability of modern equipment.

- Quality control:Find out what measures are taken to ensure product quality at all stages of production.

- Prices:Compare prices from different manufacturers, taking into account product quality and delivery conditions.

Application of plaster mesh in rolls

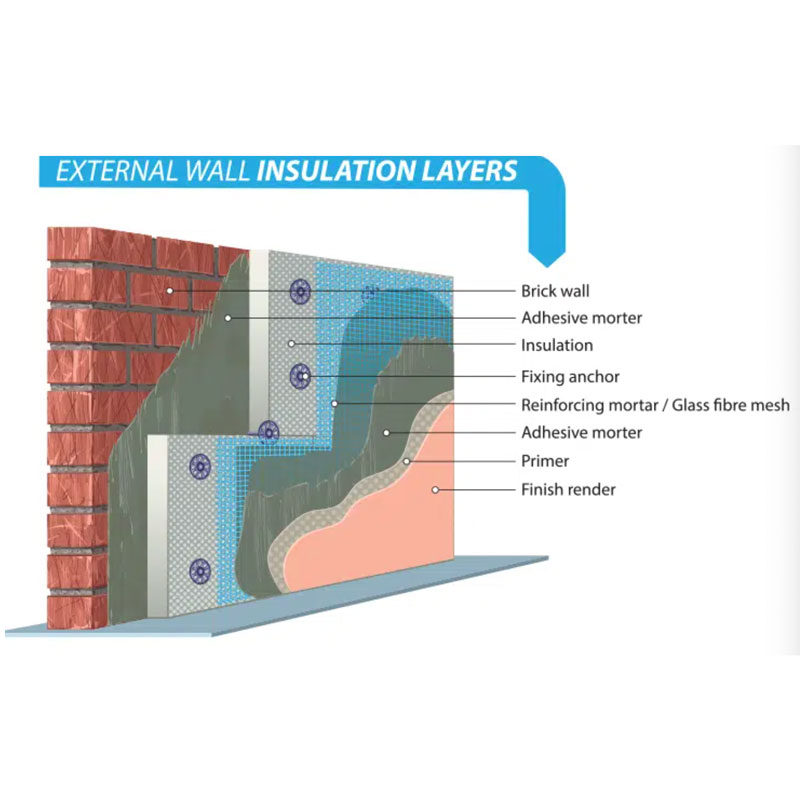

Plaster mesh rollsused in various construction works:

- Reinforcement of plaster layers on walls and ceilings.

- Strengthening cracks and preventing their further spread.

- Creates a strong base for facing materials such as tile or stone.

- Reinforcement of waterproofing layers.

- In facade insulation systems.

Advantages of using plaster mesh in rolls

Using qualityplaster mesh rollsprovides a number of advantages:

- Increasing the strength and durability of the plaster layer.

- Prevents cracks from forming.

- Improving the adhesion of plaster to the base.

- Reducing the risk of collapse of the plaster layer.

- Increasing the service life of the finish.

An example of choosing a plaster mesh for a specific project

Let's say you need to do plastering work on the facade of a building. In this case, it is recommended to use a metal mesh made of galvanized steel with a density of at least 160 g/m2 and a cell size of 10x10 mm. This will ensure sufficient strength and resistance of the plaster layer to atmospheric influences. For interior work, you can use fiberglass mesh with a density of 120-140 g/m2. For detailed advice on choosing a suitable mesh, contact our specialistsHebei Blue Diamond International Co.,Ltd.

Comparison table of different types of plaster mesh

| Grid type | Material | Density (g/m2) | Application | Advantages |

|---|---|---|---|---|

| Fiberglass | Fiberglass | 110-160 | Interior and exterior works | Alkali resistance, strength |

| Metal | Galvanized steel/Stainless steel | 160-250 | Facades, industrial premises | High strength, resistance to mechanical damage |

| Polymer | Polypropylene/Polyethylene | 80-120 | Difficult surfaces, wet areas | Lightweight, moisture and chemical resistant |

Conclusion

Choosing the right oneplaster mesh rolls– an important stage in any construction project. Taking into account the types, characteristics and recommendations for choosing a manufacturer, you can ensure the strength and durability of the plaster layer. Do not hesitate to contact specialists for advice and selection of the optimal solution for your project.

Correspondingproducts

Related Products

Best Sellingproducts

Best Selling Products-

Fiberglass woven roving

Fiberglass woven roving -

Chopped fiberglass felt

Chopped fiberglass felt -

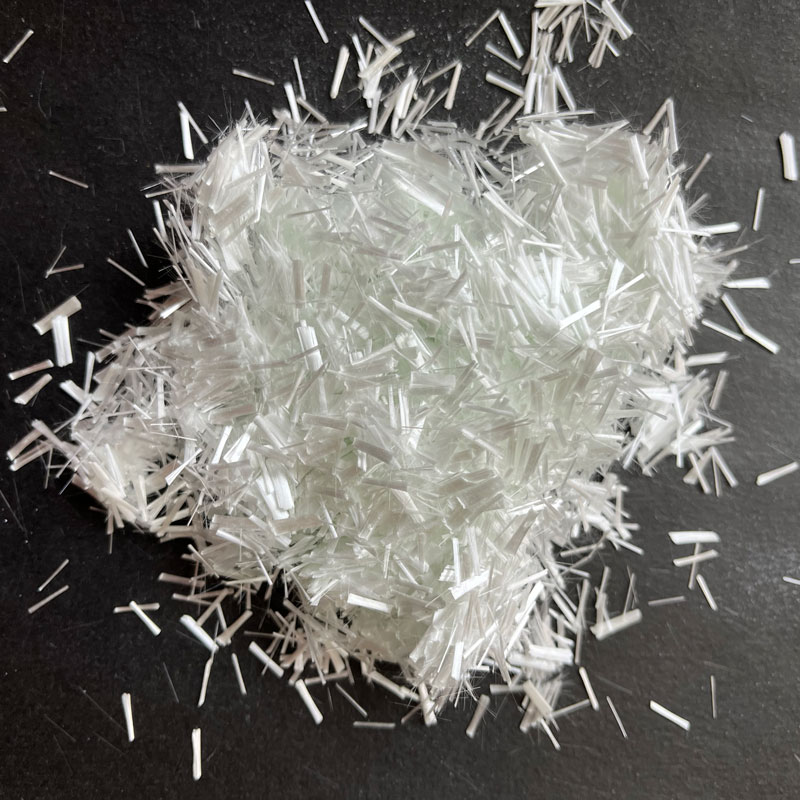

AR fiberglass cut thread

AR fiberglass cut thread -

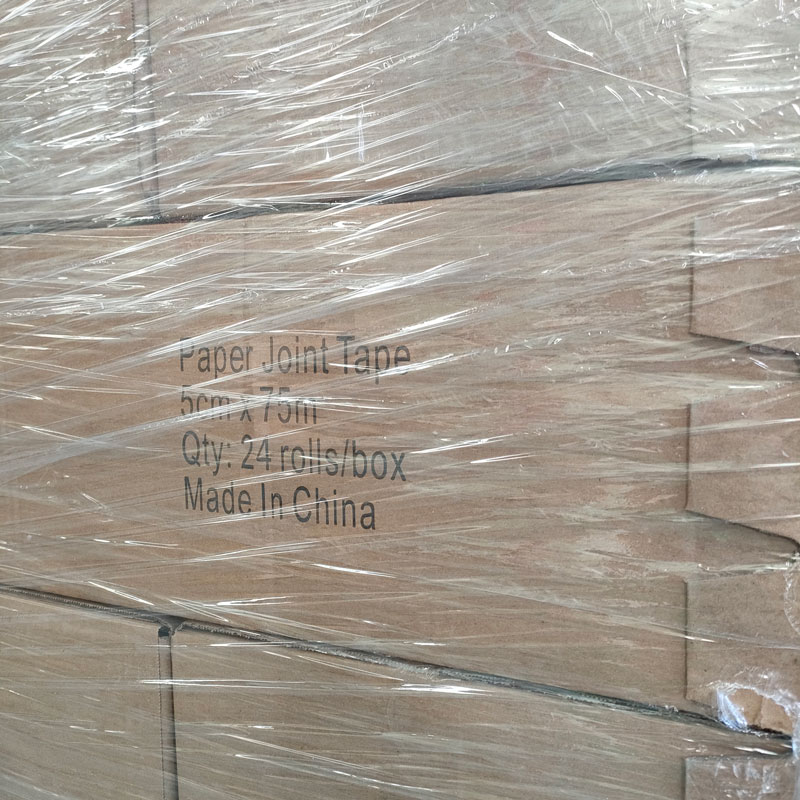

Paper connecting tape

Paper connecting tape -

Fiberglass Mesh Fabric for Reinforcement of Stone and Mosaic Substrate

Fiberglass Mesh Fabric for Reinforcement of Stone and Mosaic Substrate -

PVC corner edge

PVC corner edge -

Fiberglass mesh for roof waterproofing

Fiberglass mesh for roof waterproofing -

Fiberglass reinforced plastic board

Fiberglass reinforced plastic board -

Metal Corner Tape

Metal Corner Tape -

Fiberglass mesh tape

Fiberglass mesh tape -

Fiberglass Window Screen

Fiberglass Window Screen -

Fiberglass fabric

Fiberglass fabric

Connectedsearch

Related Search- Cheap plaster mesh manufacturers

- China Woven Plaster Mesh Suppliers

- Cheap Suppliers Fiberglass Mesh Fabric for Facade Project

- 5x5mm fiberglass woven plaster mesh fabric factory in China

- Wholesale fiberglass mesh fabric 5x5 facade mesh fabric Suppliers

- Cheap fiberglass fabric suppliers

- Cheap Fiberglass Curtain Wall Mesh Fabric 5x5 Suppliers

- Cheap alkali resistant fiberglass curtain wall mesh fabric factory

- cheap sd fiberglass plaster mesh fabric factory

- Alkali Resistant Fiberglass Reinforcement Mesh for Exterior Walls of Factories in China