Cheap alkali resistant fiberglass curtain wall mesh manufacturers

Looking for a reliable suppliercheap alkali-resistant glass fibersfor reinforcing plaster layers and producing facade mesh? In this article, we will look at the key aspects of choosing a manufacturer, compare the characteristics of different types of fiberglass, and offer useful tips for optimizing costs.

What is alkali-resistant glass fiber and where is it used?

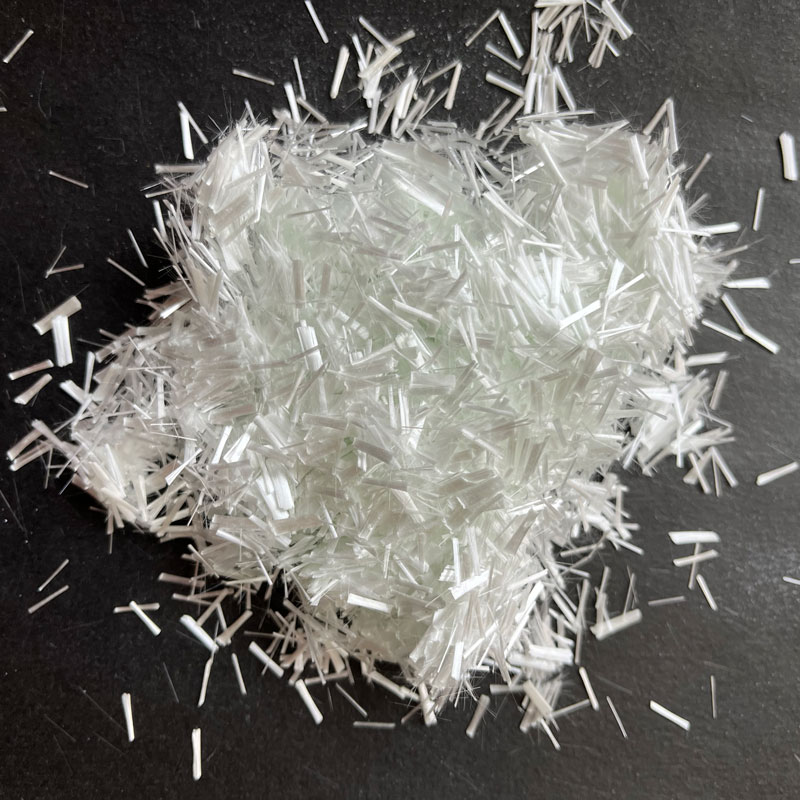

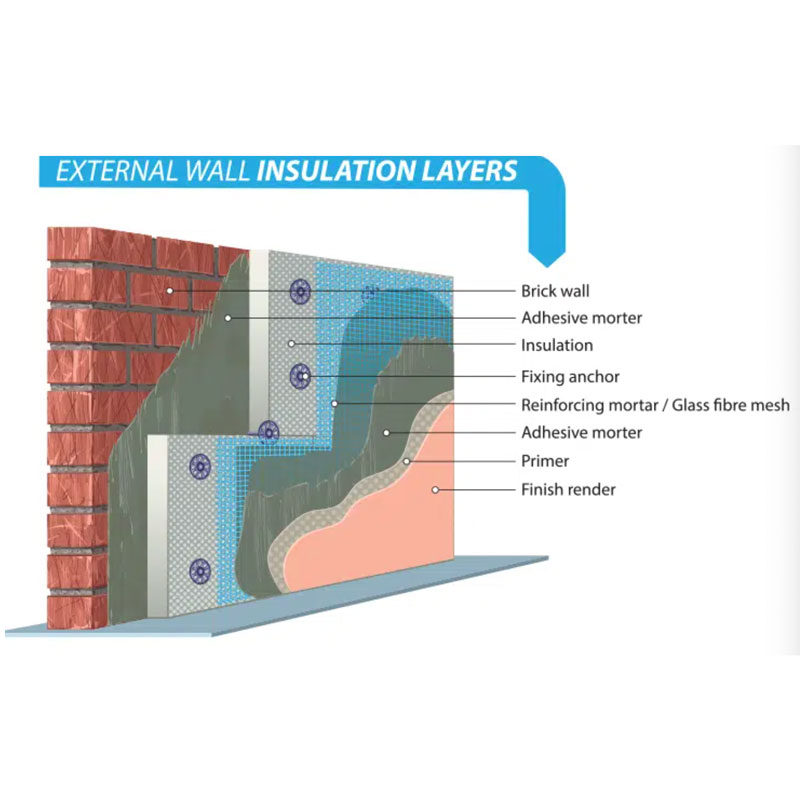

Alkali-resistant glass fiberis a special type of glass fiber designed for use in alkaline environments, such as cement mortars and plasters. Ordinary fiberglass quickly breaks down under such conditions, losing its reinforcing properties. Applications:

- Reinforcement of plaster layers on building facades.

- Production of facade mesh to reinforce plaster.

- Production of lightweight concrete structures (LBC).

- Production of roofing materials.

- Reinforcement of road surfaces.

How to choose a manufacturer of alkali-resistant glass fiber: key criteria

When choosing a manufacturer, it is important to consider several key factors:

Reputation and experience

Study the company's history, customer reviews and availability of quality certificates. Preference should be given to manufacturers with many years of experience and a positive reputation in the market.

Production facilities and technologies

Learn about the production technologies used and product quality control. Modern equipment and strict control ensure stable qualityalkali-resistant fiberglass.

Product range

Make sure the manufacturer offers a wide range of products to meet your needs for mesh size, density and tensile strength.

Pricing policy

Compare prices from several manufacturers, taking into account product quality and delivery conditions. The lowest price does not always mean the best solution. It is important to find the optimal price-quality ratio.

Logistics and delivery

Evaluate the manufacturer’s capabilities to organize delivery of products to your region. It is important that delivery is timely and reliable.

Review of manufacturers of cheap alkali-resistant glass fiber (indicative)

Important!The information below is provided for informational purposes and requires verification of relevance at the time of order.

When choosing a supplieralkali-resistant fiberglassIt is worth paying attention to such manufacturers asHebei Blue Diamond International Co.,Ltd, specializing in the production of high-quality materials for reinforcing plaster facades. Their products are highly durable and long lasting, making them an ideal choice for construction projects of any size. Hebei Blue Diamond International Co., Ltd. provides a wide range of products, including various types of fiberglass mesh, meeting the most stringent quality and reliability requirements.

The table below shows the comparative characteristics of various typesalkali-resistant fiberglass(data may vary, check with manufacturers):

| Characteristic | Type 1 | Type 2 | Type 3 |

|---|---|---|---|

| ZrO2 content | 14.5% | 16.5% | 18% |

| Density | 75 g/m2 | 110 g/m2 | 160 g/m2 |

| Tensile strength (base) | >1500 N/5 cm | >2000 N/5 cm | >2500 N/5 cm |

| Tensile strength (weft) | >1000 N/5 cm | >1500 N/5 cm | >2000 N/5 cm |

Tips for saving money when purchasing alkali-resistant fiberglass

There are several ways to reduce purchasing costsalkali-resistant fiberglass:

- Order in bulk:Large quantities are usually cheaper.

- Plan ahead:Ordering in advance allows you to avoid rushing and searching for urgent suppliers with higher prices.

- Compare offers from different manufacturers:Don't limit yourself to just one supplier, conduct a market analysis.

- Use discounts and promotions:Many manufacturers offer discounts for regular customers or for large order volumes.

- Optimize your logistics costs:Consider pickup or select the most cost-effective shipping method.

Conclusion

Choosing a reliable manufacturercheap alkali resistant fiberglass– an important step to ensure the quality and durability of construction work. Consider the manufacturer’s reputation, its production capacity, product range and pricing policy. Don't forget about the opportunity to save money by ordering in bulk and planning your purchases in advance.

Correspondingproducts

Related Products

Best Sellingproducts

Best Selling Products-

Fiberglass Window Screen

Fiberglass Window Screen -

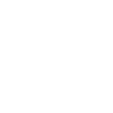

AR fiberglass cut thread

AR fiberglass cut thread -

Metal Corner Tape

Metal Corner Tape -

Chopped fiberglass felt

Chopped fiberglass felt -

Fiberglass Mesh Fabric for Reinforcement of Stone and Mosaic Substrate

Fiberglass Mesh Fabric for Reinforcement of Stone and Mosaic Substrate -

Fiberglass mesh tape

Fiberglass mesh tape -

Spray masking protective film

Spray masking protective film -

Fiberglass Mesh Fabric for EPS Special Improvement Line

Fiberglass Mesh Fabric for EPS Special Improvement Line -

PVC corner edge

PVC corner edge -

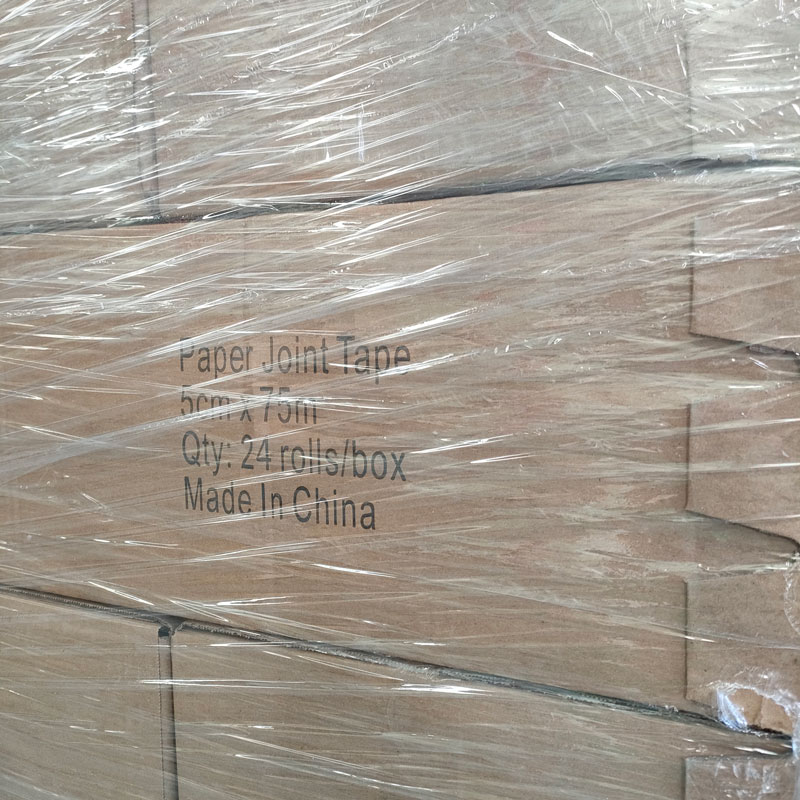

Paper connecting tape

Paper connecting tape -

Fiberglass reinforced plastic board

Fiberglass reinforced plastic board -

Fiberglass mesh fabric for wall insulation and reinforcement.

Fiberglass mesh fabric for wall insulation and reinforcement.

Connectedsearch

Related Search- fiberglass painting mesh

- metal plaster mesh 5x5

- Chinese fiberglass curtain wall mesh suppliers

- Facade fiberglass mesh Krepiks

- China fiberglass mesh painting nets manufacturers

- Chinese plaster mesh manufacturers certificates

- Chinese factories for the production of fiberglass mesh for facades (GOST)

- Wholesale fiberglass curtain wall mesh fabric 5 5mm factory

- China manufacturer fiberglass plaster mesh fabric 5x5 price exterior wall mesh fabric

- 5x5mm fiberglass woven plaster mesh fabric factory in China