What are the innovations in the production of façade mesh?

2025-01-25

content

In modern construction, facade mesh plays a key role due to its ability to strengthen and protect building facades. This is an important material that provides durability and resistance to various external influences. Today we will talk about innovations in the production of facade mesh, which have significantly improved its characteristics and expanded its scope of application. In the age of innovation On-technology manufacturers are striving to use new materials and methods to offer the market better and more effective solutions. The article will present six key aspects that cover innovations in the production of façade mesh. Among them, issues of improving strength, environmental resistance, as well as the integration of smart technologies into the production process will be considered.

On-technology manufacturers are striving to use new materials and methods to offer the market better and more effective solutions. The article will present six key aspects that cover innovations in the production of façade mesh. Among them, issues of improving strength, environmental resistance, as well as the integration of smart technologies into the production process will be considered.

Use of new materials

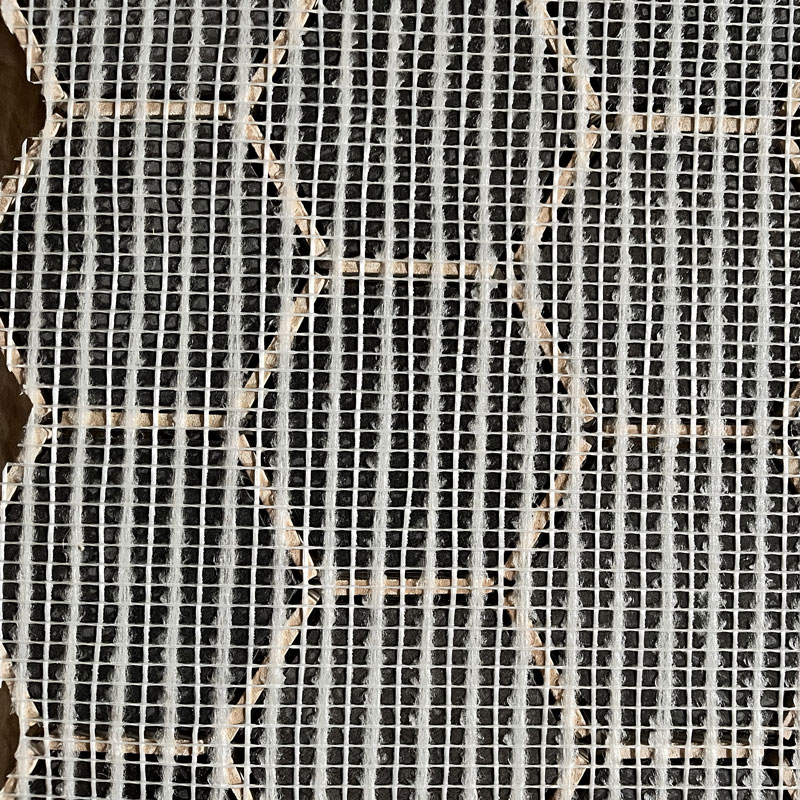

One of the most important trends in the production of facade mesh is the use of innovative materials. Traditionally, this mesh is made from fiberglass, but today manufacturers are adding polymers and composites. This allows you to increase its strength and durability. Modern materials make facade mesh resistant to aggressive chemical influences and ultraviolet radiation, which is especially important in urban environments with high levels of air pollution.Facade fiberglass meshThe plant's factory acquires new properties thanks to the use of such innovations. These changes also reduce the weight of the product, making it easier to transport and install. In addition, polymer components improve the aesthetic qualities of the mesh, making it more attractive for architectural solutions.

Technological production processes

Modern factories and factories are introducing automation and robotics to increase the efficiency of facade mesh production. Ultra-modern equipment ensures precision and high quality products at all stages of production. One such enterprise isFacade fiberglass mesh plant, which actively uses advanced technologies in its production cycle. Thanks to the use of automated processes, it is possible to reduce the number of defects and reduce production costs. Modern software allows you to accurately control each stage of the process and quickly make changes, which also improves the environmental safety of production. Thus, automation and innovation in production processes contribute to improving the quality and reliability of façade mesh.

Environmental aspects of production

Facade mesh, produced taking into account environmental requirements, is becoming increasingly popular. Manufacturers today strive to minimize their environmental footprint by using recyclable materials and reducing production energy costs. At the factoryFacade fiberglass mesh plantParticular attention is paid to the introduction of green technologies that reduce the impact of production on the environment. Through the use of recycled materials and the introduction of energy-saving technologies, production becomes more sustainable and safe for the ecosystem. This meets modern standards of responsible consumption and satisfies the needs of conscious consumers focused on environmentally friendly products.

Impact on the stability and durability of facades

Thanks to innovations in production, facade mesh has become even more durable and stable. New technologies have made it possible to increase its resistance to physical and chemical stress, which in turn extends the service life of facades.Facade fiberglass meshoptimally distributes mechanical loads and reduces the likelihood of cracks and deformations in building structures. This not only provides protection from negative external influences, but also makes it possible to use lighter design solutions. Innovations in mesh production also affect the thermal insulation and sound insulation characteristics of facades, creating comfortable conditions inside the building.

Integration of smart technologies

In the age of digital technology, the production of facade mesh has also not been left aside. Modern production is introducing smart technologies that make it possible to connect the functions of the façade mesh with electronic components. This allows, for example, to monitor the condition of a building in real time, identifying damage and predicting the need for repairs. Such solutions are especially relevant for large cities and complex architectural projects. In enterprises likeFacade fiberglass mesh plant, are actively exploring the possibility of integrating sensors and chips, which makes the product not just a building material, but part of an intelligent building management system.

Development prospects

The improvement of façade mesh does not stop there. In the future, new discoveries in materials science and nanotechnology are expected to further enhance the performance characteristics of the mesh. Developments are emerging that will allow façade mesh to actively interact with the environment, for example, to clean itself or change its properties depending on the weather. In addition to this, efforts towards sustainable production and the use of renewable resources will continue to have a positive impact on the industry. Manufacturers such asFacade fiberglass mesh plant, continue to invest in research and development to remain at the forefront of innovation in building materials, ensuring high quality and reliable products for their customers.